Welcome to the website where we bring all things electronic right at your fingertips- Electroglobal. We are a hardworking company of innovators and tech enthusiasts who are driven by a sense of purpose in helping you navigate the exciting frontier of electronics.

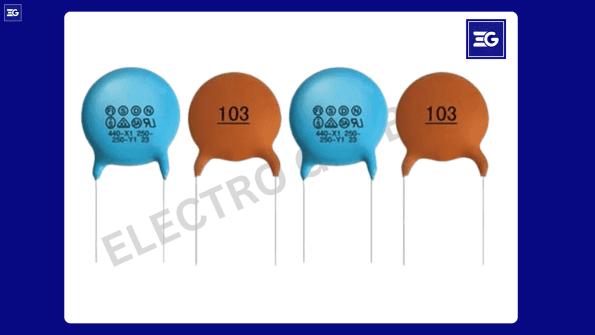

Introduction to Ceramic Capacitors

Ceramic capacitors are amongst the widely used capacitors in modern electronics since they offer numerous advantages of miniaturisation, high stability and reasonable cost. These types of capacitors employ ceramic as the dielectric, and thus they are distinguished from other forms of capacitors. This publication aims at expounding on the characteristics of ceramic capacitors while giving an insight into their utility in electronic circuits.

Understanding Ceramic Capacitance

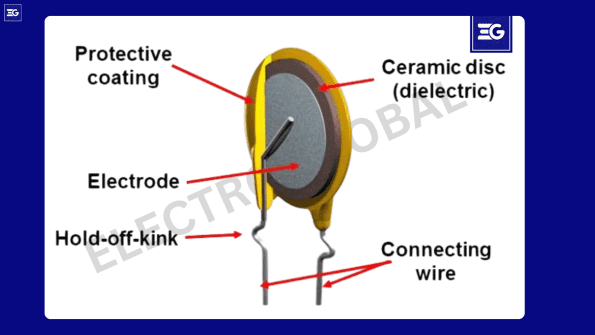

A ceramic capacitor can be regarded as a dielectric material made from ceramics with two conductive layers at its face. One of the most important benefits of using this ceramic material is the possessing high permittivity that provides much capacitance in an enclosed volume. These capacitors are typically classified into two types based on their ceramic material: Class 1 and Class 2 The second question asks for class and subclass designations in relevance to ASM’s three classes, and with few exceptions, all types of products can be classified under one of these three classes.

Class 1 Ceramic Capacitors: Class 1 capacitors, known for their extremely high stability and low loss features, are manufactured using substrates such as titanium dioxide. These devices are most suitable for environments where accurate and constant performance at various temperatures is necessary.

Class 2 Ceramic Capacitors : This type of capacitors in particular employ such dielectrics as barium titanate and have slightly higher capacitance but with a lack of stability. They are as follows: They are used mainly in circuits where higher capacitance is desirable.

Key Properties of Ceramic Capacitors

Ceramic capacitors exhibit several key properties that make them highly valuable in various applications:

- High Capacitance per Volume: Ceramic capacitors offer excellent high capacitance density in a relatively small dielectric material volume, so they are best suited for applications that require high capacitance and which have limited dimensions.

- Wide Temperature Range: It is appreciated to operate efficiently at a diverse range of temperature levels and they are ideal to function under tough conditions.

- Low ESR and ESL: Many high-frequency applications benefit from low ESR and ESL, which are the slashed ess components of the circuit.

- Reliability: Ceramic capacitors are usually of high life and come with mounting terminals, which are crucial in some circuits.

Applications of Ceramic Capacitors

Ceramic capacitors are ubiquitous in modern electronics, serving a variety of functions:

- Decoupling and Bypass : It is applied in the noise suppression technique mainly in power supply circuits where it helps to act as a buffer to voltage fluctuations.

- Filtering: Ceramic capacitors find a applications in the filtering, they can remove undesired noise from the signal in communication and such audio systems.

- Tuning and Matching: In applications related to radio frequency, these components are often employed in fine-tuning circuits for accurately matching or stabilizing frequencies.

- Energy Storage: In power management circuits, ceramic capacitors supply a needed amount of energy and discharge it at the correct interval in making for an efficient system dispatch of electricity.

Advantages of Ceramic Capacitors

Ceramic capacitors offer several advantages that make them a preferred choice in electronic design:

- Compact Size: This enables a seamless incorporation of the devices into small and easily transportable gadgets.

- Cost-Effective: First of all, they are not very expensive, which will result into them being used when developing solutions for various processes.

- High Performance: This has the effect of giving them very encouraging performance values such as esr and stability in high frequency usage.

- Versatility: These materials can be used in portable electronics, embedded systems, units in automobiles among other applications.

Get the Correct Ceramic Capacitor

When choosing a ceramic capacitor, consider the following factors to ensure optimal performance:

- Capacitance Value: Chose certain capacitance value that will be suitable for your circuit need or application.

- Voltage Rating: Make sure the capacitor voltage is higher than the maximum voltage rating of the circuit you are using you want to use the capacitor on.

- Temperature Coefficient: Select a capacitor with a specific temperature coefficient based on the Thermal conditions that is applicable to your circuit.

- Package Size: Take into consideration the space that is available and also the size of the package you are going to choose for assembling your design.

Conclusion

The ceramic capacitors are considered as the indispensable elements of the electronics since they are characterised by high reliability in addition to their relatively low cost and satisfactory efficiency. Creating an understanding of their properties and the applications it offers allows one to make decisions when creating circuits. Welcome to Electroglobal: As an associate company, we supply various types of ceramic capacitors, as well as other components for your projects and ideas. Visit our website www.electroglobal.in to go through all the proposals that we offer, and immerse yourself into the fantastic world of electronics.